C45 / DIN 1.0503 CARBON STEEL |AISI 1045|S45C

C45 / DIN 1.0503 Forged steel manufacturers and suppliers, supplied in round rods, square/flat bars, rollers, shafts, blocks and forging pieces.

C45 / DIN 1.0503 Carbon Steel is a general carbon engineering steel which is characterized by good weldability, good machinability, and high strength and impact properties after quenched and tempered. As per EN 10083 standard, it is widely used for vechiles, shafts, bushings, crankshafts, connecting rods and parts for the machine building industry and steel for axes, knives, hammers, etc.

International Standard

| EU EN |

USA – |

Germany DIN,WNr |

Japan JIS |

France AFNOR |

England BS |

Italy UNI |

Spain UNE |

China GB |

Sweden SS |

Poland PN |

Czechia CSN |

Austria ONORM |

Russia GOST |

Inter ISO |

| C45 | 1042 1045 Gr.1043 |

C45 | S45C | AF65C45 C45 |

070M46 50HS |

1C45 C45 |

C45k | 45 | 1650 | 45 |

Available Types & Range

C 45 – BRIGHT ROUNDS

16 mm to 80 mm Dia

Brand – JSW, VSP, ASP, SAIL, SLR

C 45 – ROLLED

16 mm to 200 mm Dia

Brand – JSW, VSP, ASP, SAIL, SLR

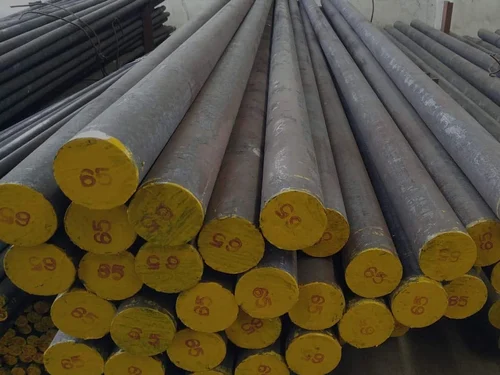

C 45 – FORGED ROUND

140 mm to 560 mm Dia

Brand – Kolkatta& Punjab Main Make

C 45 – FORGED FLAT

150 x 65 to 650 x 400 Flat

Brand – Kolkatta & Punjab Main Make

C 45 – STEP FORGED

(As per your Requirement)

Forged Condition or Machine Proof Condition

Brand – Kolkatta & Punjab – Main Make

C 45 – RING FORGED

(As per your Requirement)

Forged Condition Or Machine Proof Condition

Brand – Kolkatta & Punjab Main Make

Chemical Composition & Technical Specification – C45

| Grade | C | Si | Mn | P | S | Cr |

| C45/DIN 1.0503 | 0.42-0.5 | ≤ 0.4 | 0.5-0.8 | ≤ 0.035 | ≤ 0.035 | ≤ 0.4 |

| 1045 | 0.43-0.5 | – | 0.6-0.9 | ≤ 0.04 | ≤ 0.05 | – |

| S45C | 0.42-0.48 | 0.15-0.35 | 0.6-0.9 | ≤ 0.035 | ≤ 0.035 | – |

Equivalent Grade

| EU EN |

USA – |

Germany DIN,WNr |

Japan JIS |

France AFNOR |

England BS |

Italy UNI |

Spain UNE |

China GB |

Sweden SS |

Poland PN |

Czechia CSN |

Austria ONORM |

Russia GOST |

Inter ISO |

| C45 | 1042 1045 Gr.1043 |

C45 | S45C | AF65C45 C45 |

070M46 50HS |

1C45 C45 |

C45k | 45 | 1650 | 45 | 12050 | C45SW | 45 | C45 |

Mechanical Properties in Normalized Condition

| Diameter d (mm) | Thickness t (mm) | 0.2 % proof stress (N/mm2) | Tensile strength (N/mm2) | Elongation A5(%) |

| <16 | <16 | min. 390 | min. 620 | min. 14 |

| <17-100 | <16<=100 | min. 305 | min. 305 | min. 16 |

| <101-250 | <100<250 | min. 275 | min. 560 | min. 16 |

Forging of Carbon Steel C45 Round Bar

Hot forming temperature: 850-1200oC.

Pre heat to 750 oC – 800 oC, then continue heating to 1100 oC – 1200 oC maximum, hold until temperature is uniform throughout the section and commence forging immediately. Forging is not workable below 850 oC. Finished forgings could be air cooled.

DIN C45 Round Bar Steel Grade Heat Treatment

| Forging or hot rolling: | 1100 – 850°C |

| Normalising: | 840 – 880°C/air |

| Soft annealing: | 680 – 710°C/furnace |

| Hardening: | 820 – 860°C/water, oil |

| Tempering: | 550 – 660°C/air |

Hardening of DIN C45 Steel Hardening

Harden from a temperature of 820-860oC followed by water or oil quenching.

Heat to 820 oC – 850 oC hold until temperature is uniform throughout the section, soak for 10 – 15 minutes per 25mm of section, and quench in water or brine. Or,

Heat to 830 oC – 860 oC soak as above and quench in oil. Temper immediately while still hand warm.

Surface hardness for C45 special steel round bar after flame or induction hardening:

- Steel Name Steel number Surface Hardness

- C45 1.1191 min. 55 HRC

Application of DIN Carbon Steel C45 Round Bar

DIN C45 round bar steel material and steel plate C45, flats are widely used in all industry for uses which require more strength and wear resistance than the low carbon mild steel.

Quenched and subsequently tempered steel for C45 steel grade round bar, steel plate, flat and square is used for axles, bolts, forged connecting rods, crankshafts, torsion bars, light gears, guide rods, screws, forgings, wheel tyres, shafts, sickles, axes, knives, wood working drills, hammers, etc.

Welcome customers to inquiry DIN C45 round bar, CK45/1.1191 steel plate, flat steel for C45 steel price. We are professional supplier for more than 20 years.