EN 8 D

EN8D is a grade commonly used for making high-strength steel components. It is a medium carbon steel that is characterised by its high ductility and machinability. EN8D steel bars have a carbon content of 0.40-0.45% and a manganese content of 0.70-0.90%.

EN8D steel bars are known for their excellent mechanical properties, including high tensile strength, good wear resistance, and good fatigue resistance. They are also known for their good machinability and weldability. These properties make EN8D steel bars suitable for use in various applications, including the construction of machinery and equipment, automotive components, and other high-strength steel structures.

EN8D steel bars are also known for their good surface finish and dimensional accuracy, which makes them suitable for use in precision engineering applications.

EN8D steel bars are typically supplied in the as-rolled condition, but they can also be supplied in the heat-treated condition. The heat treatment process can improve the mechanical properties of the steel, making it even stronger and more wear resistant.

Internal Standard |

BS |

DIN |

IS |

EN |

SAE/AISI |

EN8D |

080A40 |

CK45 |

45C8 |

EN8D |

1040, 1045 |

Available Types & Range

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ16 – Φ650 | Standard or As your request |

| Square bar | 25 x 25 – 450 x 450 | Standard or As your request |

| Plate/Sheet | Thickness :1 – 300 Width: up to 2500 |

Standard or As your request |

| Flat bar/Forged Flats | Thickness :10 – 500 Width: 25 – 650 |

Standard or As your request |

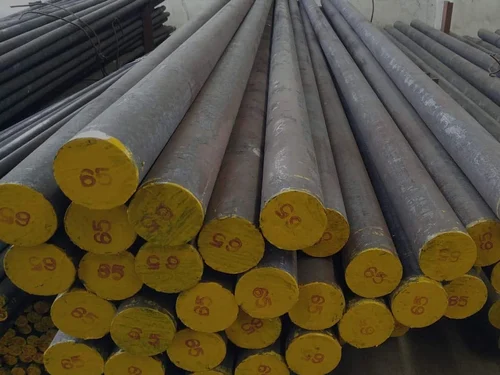

EN 8D – Rolled

size – 6 mm to 200 mm Dia

Brand – JSW, VSP, ASP, SAIL, SLR

EN 8D – BRIGHT ROUNDS

size – 6 mm to 63 mm Dia

Brand – JSW, VSP, ASP, SAIL, SLR

EN 8D – FORGED ROUNDS

Size – 140 mm to 670 mm Dia

Brand – Kolkatta& Punjab Main Make

Chemical Composition & Technical Specification EN 8D

Element |

C |

Mn |

P |

S |

Content (%) |

0.40-0.45 |

0.70-0.90 |

0.045 Max |

0.045 Max |

Mechanical Properties:

Grade |

Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Elongation in 100-150 mm(%) |

Reduction in Area |

Hardness |

En8D |

≥380 |

≥210 |

≥25 |

≥50 |

≤111HB |

Applications of EN8D

EN8D is extensively used where more strength and wear resistance is required than low carbon mild steel and where higher strength of low alloy high tensile steel is not necessary. Example: Motor Shaft, axles, hydraulic rams and medium to high strength threaded fasteners are required

Typical components include transmission shafts, spindles and small gears, high tensile threaded fasteners such as bolts, nuts and studs.