EN3B

EN3B is a general engineering steel which is suitable in

applications where heavy stresses and heat treatment are

not involved. It is a bright drawn / turned mild steel with

good machinability but poor hardenability, and is used in a

variety of general engineering applications. EN3B can be

case hardened and is normally used in the supplied

condition. The material promotes good weldability

characteristics.

International Standard

| BS 970 1991 | BS 970 1955 EN | AISI/SAE | Werkstoff |

| 070M20 | EN3B | 1020 | 1.0402 |

Available Types & Range

| Form of Supply | Size(mm) | Length(mm) |

| Rolled bar | Φ20-Φ 125 | Standard or As your request |

| Square bar | 25 x 25 – 450 x 450 | Standard or As your request |

| Plate/Sheet | Thickness :6 – 300 Width:80-1,250 |

Standard or As your request |

| Forging | Φ 140 – 560 | Standard or As your request |

EN 3 B – ROLLED

Size – 16 mm to 200 mm Dia

Brand – JSW, VSP, ASP, SAIL, SLR

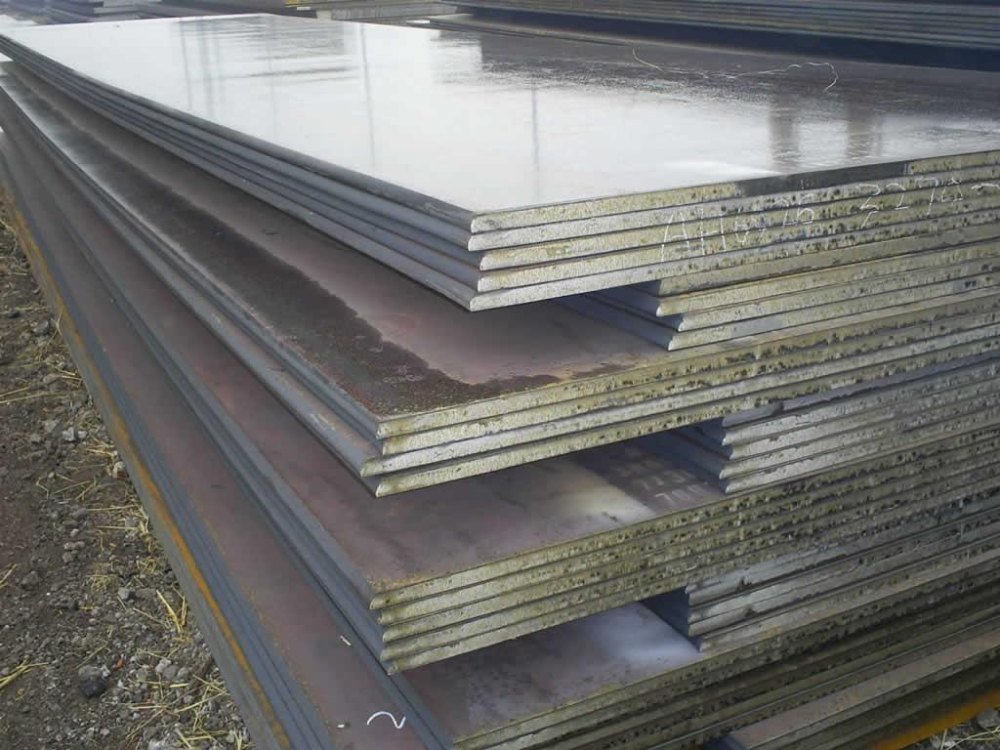

EN 3B SHEET

Thickness :1 – 300 ( mm)

Width:80-1,250 & 2500 ( mm )

(As per your Requirement)

EN 3B FORGED ROUNDS

Dia – 140 – 560 mm

Length – 3 – 5.5 mtr

Brand – Kolkatta & Punjab Main Make

(As per your Requirement)

Chemical Composition & Technical Specification EN 3 B

| C | Si | Mn | Ni | Cr | Mo | S | P | ||

| % | % | % | % | % | % | % | % | ||

| 0.25 Max | 0.35 Max | 1.0 Max | – | – | – | 0.06 Max | 0.06 Max | ||

Mechanical Properties

| Condition | Tensile StrengthMPa Min. | Yield StrengthMPa Min. | Elongation % |

| Cold drawn | 560 | 440 | 10 |

| Turned & Polished | 430 | 215 | 21 |

Weldability

Good.

Key features:

• Suitable for low stress engineering applications

• Can be case hardened

• Good for general machining

• For general engineering use

• Good weldability

Machinability

Good general machining

Applications

• Shafts & rollers

• Machinery parts

• Threaded bars

• Spindles & axles

• Low stress engineering applications